Plate heat exchanger in plants for biofuels and renewable resources

Biofuels are produced from biomass, the most common types being biodiesel, bioethanol and biogas. Plate heat exchangers are used to heat and cool liquids and gases, or as condensers and reboilers in distillation columns. Biomass must often be heated for further use and dried. In the recovery of renewable feedstock such as starch, cellulose and sugar, heat exchangers for heating, evaporation and heat recovery are used. The different consistency, and solid content, of the feedstocks, means different types of heat exchangers are required.

The following examples show the experience of GESMEX in these areas:

Biodiesel plants

Biodiesel is made from vegetable oils, such as soybean, sunflower or palm oil or from animal fats, by a chemical reaction with methanol. Heat exchangers are used in various process stages for pre-heating, glycerine heater and cooler, and in the methanol distillation, as economizers.

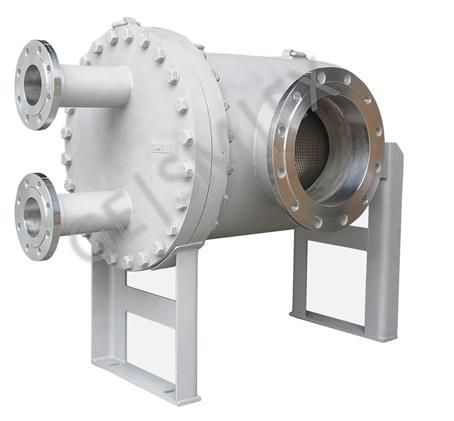

All welded construction of the XPS - Plate & Shell heat exchangers is recommended for high temperatures or pressures, or if chemical attack of ingredients excludes the use of plate and frame heat exchangers with gaskets. XPS units are currently operating as methanol - condenseors or feed / effluent heat exchanger.

- Type:

- Plate & Shell, XPS 50

- Variant:

- fully welded

- Features:

- max. 120 bar, 300 ° C, multi-pass on both sides

- Installation site:

- Scotland

Bioethanol plants

Bioethanol is produced by the fermentation of sugars, such as sugar beat or cane, hydrolysed starch from cereals, or cellulose. Heat exchangers are used in bioethanol plants as mash heaters, reboilers, overhead condensers or as economizers in distillation columns and heat recovery.

XPS - Plate & Shell heat exchangers are operating as condensers, for condensing ethanol vapor after distiallation or ethanol cooling.

XPT - Thermo Plate heat exchanger can be used as heating plates in flooded reboilers to concentrate mash.

- Type:

- Plate & Shell, XPS 100

- Variant:

- openable

- Features:

- to 200 ° C, -1 to 10 bar

- Installation site:

- China

Biogas plants

Biogas can be produced from the fermentation of biological waste, such as biproducts from bioethanol, or from other biomass. Heat exchangers are used for sludge heating and cooling andcondensering to dry steam-saturated biogas.

XPS - Plate & Shell heat exchangers are particularly suitable for use in clean media and as condensers.

XPT - Thermo Plate heat exchangers are used for heating and cooling sludge or other contaminated media.

- Type:

- Plate & Shell, XPS 100

- Variant:

- openable

- Features:

- cross-flow to minimize pressure loss at the shell side

- Installation site:

- Schweden

Biogas drying

Biomass drying systems are as diverse as the material to be dried, and the consistancy can vary greatly: liquid as digestate, a slurry, or particulates, such as grain or wood chips. Heat exchangers are used for heating the biomass, combining preheating and heat recovery from exhaust air.

XPT - Thermo Plate heat exchangers are especially suitable for these applications. The heat transfer surfaces can be produced in different types and sizes. They can be used both as a heating jacket or internal heating surfaces. The heating media can be distributed by welded flow channels for uniform and gentle drying on the plates.

- Type:

- Thermal Plate, XPT

- Features:

- heating medium steam, complete heating of the vessel shell

- Installation site:

- Denmark

Starch production and processing

Starch is mainly produced from maize, wheat, potatoes and cassava. After crushing and washing the raw material, heat exchangers are used for heating and cooling starch solutions for saccharifion of the starch, evaporatoring for concentrating the hydrolyzed starch, or for cooling of concentrates.

XPT - Thermo Plate heat exchangers are used, if the product contains solids, as with shredded raw materials, or if the product is highly viscous, such as concentrates.

XPS - Plate & Shell heat exchangers are utlised for cleaner media, such as pre-heating of process water, cooling of products or heat transfer fluids and for condensing exhaust steam.

- Type:

- Plate & Shell, XPS 50

- Features:

- multi-pass on both sides for a long thermal length and close temperature approach

- Installation site:

- Germany

Sugar production

Sugar is produced from sugar beet or cane. The crushed raw material is mixed with hot water to extract the sugar. The raw juice is then concdentrated by evaporation, increasing the sugar content before crystalisation. Heat exchangers are also used for pasteurization, cooling syrup or heat recovery.

XPT - Thermo Plate heat exchangers are used in direct contact with sugar solutions. Their design allows a good cleanability as well good surface temperature control to avoid burning the product.

XPS - Plate & Shell heat exchangers are often used as a steam-heated preheaters of process water.

- Type:

- Plate & Shell, XPS 100

- Features:

- openable shell for quick replacement of the plate pack to minimize downtime

- Installation site:

- Germany

Pulp & paper production

Pulp is obtained from plant fibers, wood is shredded and in a cooking process in reactors, chemically macerated, forming pulp. For papermaking, the pulp is mixed with preheated water. During the production process recycled white water is preheated again for further use.

XPT - Thermo Plate heat exchangers have free flow channels and can be used for heating the fibrous white water without clogging.

XPS - Plate & Shell heat exchangers are used to heat up water for the milling process or in paper production.

- Type:

- Plate & Shell, XPS 100

- Variant:

- excentric shell

- Features:

- heating medium: stream with internal distributor to avoid maldistribution

- Installation site:

- Finland

Heat exchangers in utility systems and for heat recovery

In addition to process-specific tasks, GESMEX plate heat exchangers are also used in numerous auxiliary and utility systems, such as: heating of cleaning solutions, cooling lubricant oil, drying copmressed air, jacket cooling, ...

GESMEX plate heat exchangers are used for heat recovery from exhausst vapors or flash steam, in sewage systems, for heat recovery or power generation from waste gases ...